Finding the right equipment for your business might seem like an impossible task. With so many different manufacturers and models, it’s an ocean of opportunities. We talked to our lab manager, Kaya Carretta, and some of our customers to find out how they made these decisions.

Your roaster is a big investment and you know you need to do your homework. If you make the right choice, it will be with you for many years, but what should you investigate before taking the plunge?

It’s all about them dollas, dolla dolla bill y’all.

Step 1: Figure out how much you have to spend.

Step 2: Buy the roaster you can afford.

Sounds simple, right? Of course it’s not. Here are some things to consider.

Upfront costs

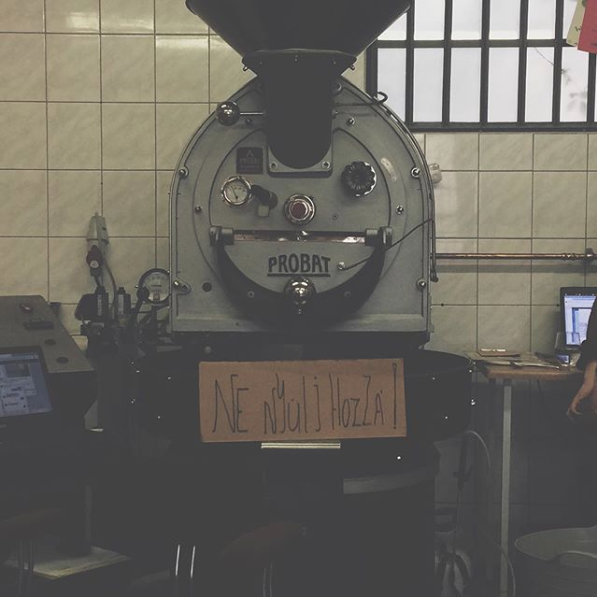

Different brands have different prices, depending on where you are located in the world. Casino Mocca in Hungary bought a refurbished Probat from the 1950s, and it was a huge investment for them.

“Seven years ago, when we started the business, the Probat was really expensive second-hand, almost the same price as a new one,” said green buyer, Lajos Horvat. After trying several different machines they decided the Probat was worth the money as it offered the flavour profile they wanted to give their customers.

Ongoing costs

After the initial outlay, you should consider the ongoing expenses.

Fergus Brown of Roasted Brown in Ireland invested in a Loring because he knew the operational costs would be lower. “It uses up to 50% of the energy of a drum roaster,” he said. Where Fergus operates, that’s a saving of around €200 a month.

Size matters

Beyond your wallet, there are many other considerations when choosing a roaster, and size is a big one. (See what I did there?)

What kind of volumes will you be roasting now and in the future?

When he began his roastery Fergus bought the machine he would need in the future, not the machine he needed on his first day. He decided on a 35kg Loring, and immediately ruled out the smaller version. “To spend that amount of money on a 15kg roaster is madness! You can’t scale,” he said. “You should also keep in mind that as your business grows, a bigger machine means less staff costs. We would need at least one more staff member and a considerably bigger workshop if we had a smaller machine, as production would be a lot more intense everyday. This is a massive saving and that money can go directly into paying off your asset quickly,” he added.

For Bonanza Coffee in Germany, the 45kg capacity of their Van Gülpen can be frustrating when it comes to smaller volume high-quality lots. “If you only have 24kg, you don’t want to try one-shotting it in an underfilled capacity drum,” said green buyer, Scott Tedder. Similarly managing small orders can be challenging with such a large capacity roaster. “When someone orders 15kg of coffee, we either roast 45kg and have a lot of overstock, or we roast five batches in our 3kg machine and risk inconsistency.” Scott said Bonanza usually roast 45kg and send the overstock to their cafe. It’s a good solution, but not all roasteries have this option.

Will the machine fit in your roastery?

Another consideration is what kind of space will you be working in, and can the machine fit? Drum roasters need space for the exhaust pipes and afterburner. Silja Löfgren learned to roast on a Probat but switched to a Diedrich 12kg when she started roasting for Good Life Coffee Roasters in Finland. It wasn’t just the airflow that took some getting used to, she also had to adjust to the new space. “The room is different than where I roasted before. Now we have a short pipe to the outside so the weather affects us more. If it’s windy, or high humidity, I have to adjust the roast profile quite a lot.”

Where to get help

Shipping your roaster is a one-off cost, but maintenance is forever. Will you be able to find spare parts and service expertise when you need them? Is there a nearby distributor? Alternatively, do you know your way around a machine? Generally older roasters have technical information online, and more spare parts in the market. Newer style machines might need a specialised service person.

Jan Hrňa of Candy Cane Coffee in Czech Republic is very happy with their Mill City Roasters 20kg roaster. “It is a well built machine and it provides nice control as well as good data information,” he said. However, maintenance is an issue. “The limitation is getting technical support from the USA, especially the time zone difference.”

Keep it clean

How easy is it to clean the roaster and keep it ship-shape? Consult the jungle telegraph. Perhaps you can watch as someone else cleans their roaster so you can see how much work is involved.

Are you a control freak?

I ask in the nicest possible way.

Different machines give you different levels of control. Are probes, screens, flows and speeds your thing? If so, then maybe you should look at a high-tech option or consider how you can upgrade an older model.

Bonanza’s Van Gülpen might be considered vintage, but has been retrofitted with all the mod cons. “We pretty much have control over everything,” Scott said, “airflow, drum speed, cooling fan, drum pressure.”

Andrew Lee of VCR in Malaysia loves his 6kg Geisen for its versatility. “You can adjust the drum speed, air pressure and the flame,” he said. Having so many variables was a little daunting at first, but a cooking analogy helped Andrew get his head around this style of roasting. “I used to imagine coffee roasting like frying an egg, which is almost stationary. That doesn’t work with a Giesen. Now I imagine it’s like frying rice in a wok. There is heat from the wok but also heat from the convective airflow coming from the flames, and tossing the rice is akin to setting the drum speed,” he explains.

Patrick Groenewold of Single Estate Coffee Roasters in The Netherlands likes the instant response he gets from their 15kg Loring. “It reacts on the spot,” he said, “you don’t have the retained heat from the drum so if you turn the heat down, it goes down in a split second.”

Fergus agrees. “With the Loring I have more instant control and much more flexibility, It allows me to take a myriad of approaches to roasting a batch and this means we can really play with developing different flavours with techniques outside of the more staple parameters,” he said.

Geisen at VCR

Loring at Single Estate Coffee Roasters

Environmental impact

We all want our children, or nieces, or nephews, or godchildren or just those cute kids out on a school excursion to enjoy coffee in the future, right? Well, then we need to make this business environmentally sustainable. Coffee roasters emit various pollutants including methane, carbon monoxide and nitrogen oxides.

Installing an afterburner is one way to deal with these emissions. Drum roasters use a burner to heat the drum, and an exhaust system to push the resulting smoke out of the roaster. An afterburner will burn this coffee smoke at super high temperatures before releasing that air into the atmosphere. Afterburners do a good job of reducing pollutants, but they also expend a lot of gas. In some cases afterburners can double or even triple the amount of energy required to roast coffee.

The Loring was created to be more energy efficient and as a result it is one of the most environmentally friendly roasters available. Air is heated by the burner, then recirculated through the coffee repeatedly, burning smoke in the process. The heating of already hot air takes minimal energy, so the Loring saves on gas too.

Drum, Air or Hybrid

After budget, this is probably the deciding factor for most new roasteries. Drum roasters work by applying conductive heat to the coffee via a heated drum. Air roasters use convective heat by pushing hot air through the beans. Different style roasters create different profiles, and this is a matter of preference.

Fergus likes the Loring’s airflow style roaster for producing balanced profiles. “With the Loring we can really balance lightness and sweetness and a bit of extra body,” he said. “Quite often on a drum roaster to gain in one area you have to sacrifice in another.”

Scott believes the conductive heat of their older Van Gülpen drum roaster is ideal for omni-roasts, meaning a single roast that can be served as both espresso and filter. “To fully develop a coffee for espresso you need to roast it relatively long and then you start losing some of the nuances for filter,” he said. “Because our roaster is made out of cast iron, the pure heat transfer of that mass means we can fully develop the coffees in a short time. We can develop the coffee so it’s nice and sweet and also acidic and floral.”

Try before you buy

Jan sums it up succinctly:

“There is a lot of bullshit in our industry. I don’t believe anything until I‘ve tried it.”

You have your roaster, now what?

Congratulations on your new baby! While you wait for it to arrive, it is time to start planning your menu.

0 Comments