Our sourcing strategy

Ethiopia is our largest portfolio and origin by volume. In order to get access to the best coffee at the best exportable quality, we put people on the ground. Our sister company, Tropiq, has a representative office and team in Addis Ababa. We generally work in the Southern Nations, Nationalities, and Peoples’ Region as well as Agaro in the West.

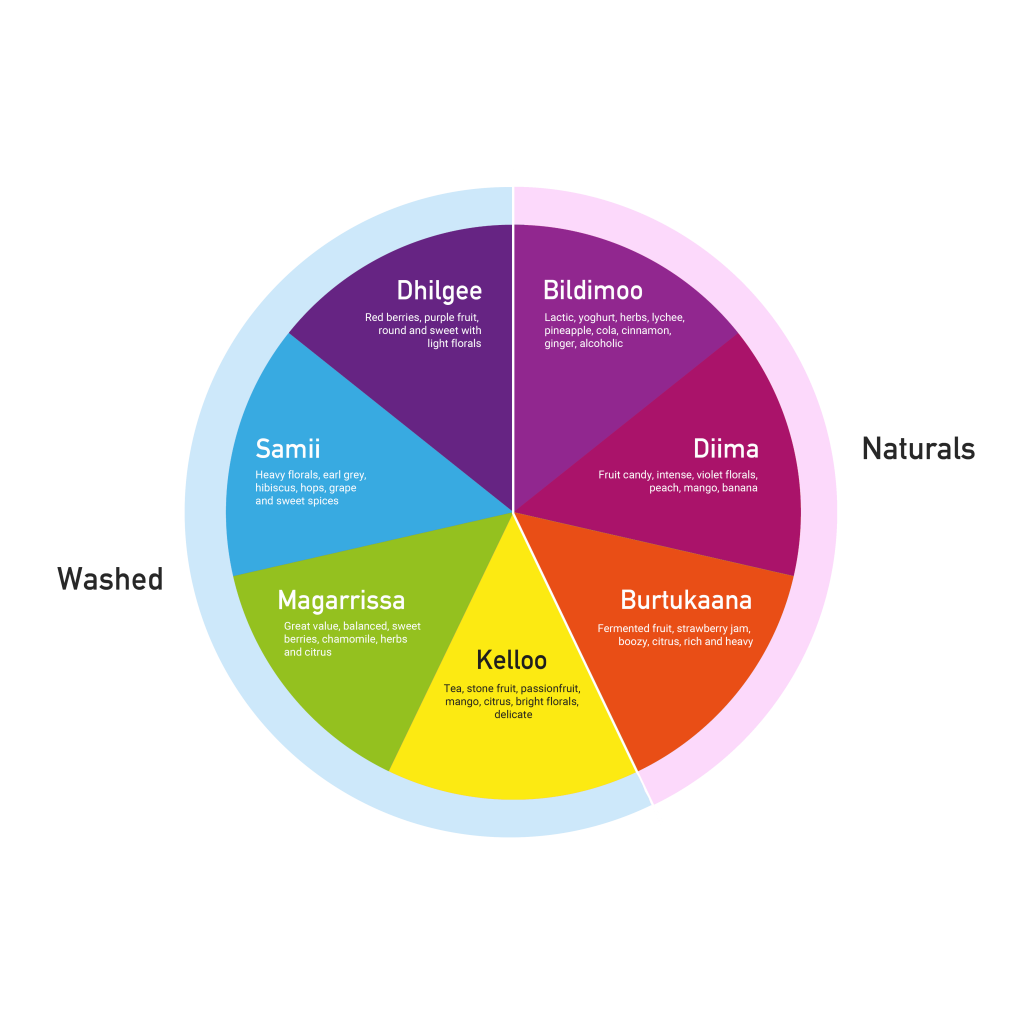

The cup profiles

Quality in the cup is for the most part defined by distinctiveness of flavour, balance and cleanliness. That said, we cup thousands of coffees per season in order to make a final selection. With the geographical diversity and share size of coffee regions, we look for distinctive, exceptionally clean and atypical coffees that represent the terroir to its fullest. To maintain the quality that is sourced, we are present from selection to shipping of the container.

Until three years ago, Ethiopian coffee was mainly traded through the ECX. There, coffees were brought in as regional blends and auctioned off to the highest bidder. This is why some people might ask for coffees such as “typical Sidamo profile”. But with the development and privatisation of the coffee sector, new profiles are being discovered and broken down in the already famous regions.

Here are the profiles that we seek in Ethiopia:

Here are the profiles you’re likely to find in the different regions:

Guji:

Uraga: Samii, Kelloo and Diima.

Hambela: Samii and Bildimoo

Shakiso: Burtukaana

Sidamo:

Yirgacheffe: Samii and Magarissa

Gedeb: Samii, Kelloo and Diima

Worka: Kelloo, Diima and Bildimoo

Bombe Mountain: Burtukaana and Bildimoo

West Arsi:

Nensebo: Dihlgee, Bildimoo and Burtukaana

Jimma

Agaro: Samii, Kelloo and Magarissa

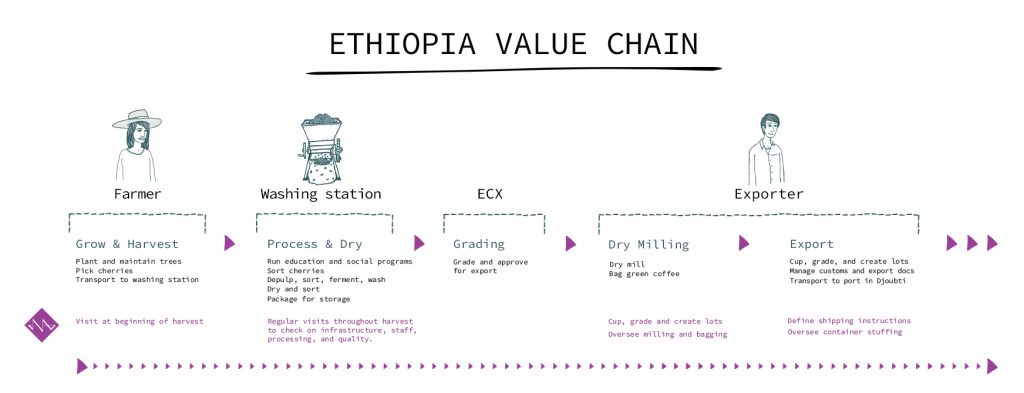

The value chain

Farmers are typically smallholders with around 0.25-2 hectares of land. Cherry is usually sold and delivered to washing stations. These stations are either owned by or vertically integrated with an exporter. Parchment is delivered to an ECX checkpoint for grading. Once certified exportable, parchment will then be cleaned and sorted, ready to be cupped by buyers.

Varieties

The varieties are referred to collectively as Ethiopian Heirloom, which is a myriad of local native Typica hybrids and new improved varieties based on the old strains. Some are named with a code such as 74/112 and 74/110 developed in the 1970’s at the Jimma Agricultural Research Center (JARC) for resistance to the coffee berry disease. These two varieties begin with “74” to indicate their cataloging and selection in 1974.

Planting and production

On average farmers own less than 1 hectare. Most coffees are organic by default with seedlings provided by the Jimma Agricultural Research Center. Organic compost is common, pruning practices less. A farmer can typically have less than 1500 trees per hectare, and 1 tree typically produces cherries equal to less than 100 – 200 grams of green coffee.

Background info

Linguists have determined that the earliest reference of coffee in Ethiopia is in Arabic documents dating back to the year 900. The documents refer to a strange new drink called “buna” that was being consumed throughout the country; “buna” is Oromiyan (a language spoken in Ethiopia) for coffee.

Arabica coffee has always grown wild in the hills of the Kaffa districts, so many coffee farms were established in those areas. Today 98% of the Ethiopian coffee farmers are small scale. Because coffee still grows wild in many areas, farmers harvest their crops utilizing 4 different systems: forest coffee, semi-forest coffee, garden coffee, and plantation coffee.

At a glance:

Harvesting season: October- January

Arrival times: April – July

Quantities: 50 – 100 bag lots

Packaging: 30 or 60 kg grainpro bags

Price levels: 10,00 – 12,00 USD/kg

Cultivars: Heirloom, improved varietals from research center

Processes: fully washed and natural, dried on raised beds

Flavour profiles: Fruit juice, fruit tea, floral, elegant

Usage: Widely used for filters, as single origin espresso and in espresso blends.

Shelf life: Normally holds up well for a year, sometimes longer.

Ethiopia videos:

Ethiopia blog posts:

HAMBELA CARDAMOM #1 – Coffee of the Month- October

Hambela Cardamom #1 Hambela Cardamom – The perfect Ethiopian Christmas coffee. Long and spicy aftertaste. Why this coffee stands out? It is not every day that we come across a coffee with distinctive cardamom flavors. When processing this washed coffee, cardamom was added, and the result does justice to its name. Despite the […]

BURTUKAANA DANCHE #1 – coffee of the month – July

Burtukaana Danche #1 Burtukaana Danche #1 – perfectly structured and sweet coffee with the counterpoint of delicate florals, that evokes the wonderful sweet taste of natural Ethiopian coffee. Why does this coffee stands out? There has been an increased interest in this coffee in the Nordic countries (they like Burtukanna […]

Ethiopia: Natural Vs. Washed (Survey)

Loving Ethiopian coffee? Natural or washed? Today is all about coffee from Ethiopia – Natural Vs washed. Take this short survey and help us learn more about what the specialty coffee community prefers. Laster inn … Problems filling the survey Ethiopia: natural vs. washed? You can go directly here. Survey We […]