“Our goal from day one was to develop and manufacture a state of the art coffee roaster.”

In this blog post, I am going to introduce you to ROEST and what is their story with sample roaster. A sample roaster is essentially a coffee roaster that was built with really small volume capacity in mind. We are talking about 100 grams of green coffee per roast and this is one of the major tasks in Nordic Approach’s coffee lab right now, to roast and send out samples to our customers around the world. ROEST is hoping with their newly designed sample roaster, it will make sample roasting easier than before.

So, I sat down with masterminds behind ROEST: Trond and Sverre (who are brothers, in case you were wondering)to talk about their project and of course, we drank coffee too.

It all Started with a Fatal Demonstration.

Back in 2013 when Sverre was working on his master’s degree in mechanical engineering he developed a one kilo coffee roaster and wrote his master thesis about energy efficiency in coffee roasters. Sample roasting is still nowhere near the horizon at this point.

From early on, he contacted Tim Wendelboe to get inspiration and knowledge and in the autumn of 2013 he and his brother gave Tim Wendelboe and Morten Wennersgaard a demonstration.

“It was a interesting demonstration although the roast was bad.” Trond said, ” we forgot to bring one of the fans and we didn’t get enough airflow through the roaster.” But, what happened during the discussion afterwards later proved to be crucial for their future adventures.

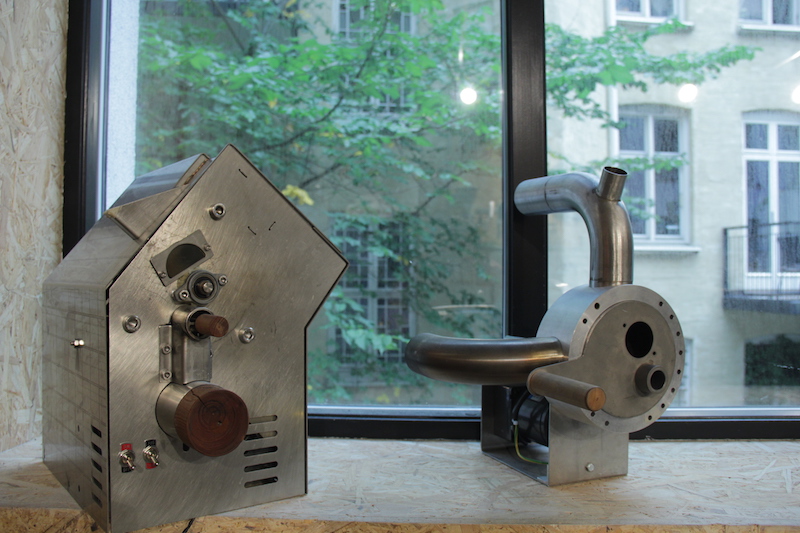

“Why don’t you guys make a new sample roaster?” Trond recalled that they were shown the two barrels probat roaster which was used in the office. “I remembered very clearly that 45 mins after I got back home that day, Sverre showed up with a drawing for a sample roaster”

From that sketch in 2013 to this day, the same concepts had been used in various prototypes.

From Side-project to the Main Show.

It remained as a side project until they won a grant from Innovation Norway, which allowed them to lift off their side-project to a full-blown endeavor. “During this development process, Morten from Nordic Approach has been really helpful and has commented on all of the prototypes. Tim also has seen most of them and given valuable feedback.”

The coffee lab in Nordic Approach became one of the pilot customers in 2016, from earlier prototypes till now Nordic Approach feels really excited to see the development and transformation of this amazing project.

You should only worry about the roasting!

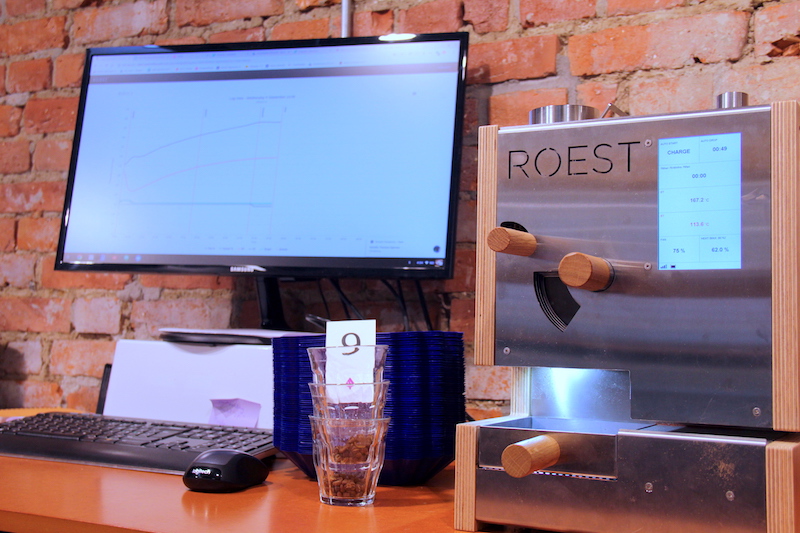

For users with or without roasting experience, they will be surprised by how easy it is to use with a straightforward digital interface, but also the degree of control from fully automatic to fully manual. For ROEST, this is exactly the kind of user experience they want to present. But, it was no small feat to arrive at this point.

“The biggest difference designing a sample roaster and a one-kilo roaster is more flexibility, especially as it gave me more freedom on how to engineer it. For small volumes like sample roasting, you don’t need to use so much energy whether it’s from electricity or gas.” Sverre recalled the design concepts and various challenges which had to be solved. “

But of course there are also big challenges when you are designing a small sample roaster compared to bigger roaster. One of the biggest challenges in the development process was to get a decent reading on bean temperature. After many trials and errors, he can now say with confidence that this is the only sample roaster out there, with decent bean temperature reading.

“I want whoever who is using this machine to have nothing to worry about but roasting itself.” Sverre reiterates the core design principle throughout our talk. In their transition from gas power to electricity, the same principle can be seen manifested itself too, You can read more about it here. “The roaster is designed for companies like Nordic Approach who needs to roast numerous different samples consistently, but also all the way down to the coffee farms.” Trond explained, “We also believed it is the perfect roaster for educational purposes since essentially we have all the functions of a larger shop roaster, with the flexibility of roasting manually or automatic. And of course you don’t need to worry about wasting too much coffee.”

First Hand Experience at Nordic Approach Coffee Lab.

Over in the coffee lab at Nordic Approach, it has around 2000 different coffees per year coming in and they all need to be roasted and cupped. Having a sample roaster which excels in consistency, efficiency, and ease of use is crucial for our operation. Nordic Approach has been giving feedback to ROEST since its inception, and the crew at the coffee lab felt excited to work with them closely for two months as one of the pilot customers and to witness its gradual improvements.

The fun part of being a pilot customer located right upstairs is all their suggestions get answered swiftly. For example, in the earlier model they suggested to reduce the noise and less than two weeks later, improvements were done and even added to the newer model.

They were using a gas-powered Probat sample roaster before ROEST, which relies heavily on personal experience and manual approach, one of the biggest challenge was the inaccurate temperature readings. “Once we had a 150 degrees reading on our sensor and in reality it was almost 300 degrees already.” Can, the lab assistant has experiences with the previous Probat and the current ROEST.

In his experience, it was a great improvement on consistency, efficiency and how straightforward it is to use. In the coffee lab, fine-tuning roast profile for every sample will be almost impossible because of the large numbers of different coffees, thus, the ability to roast in a continuous flow is crucial to maintain a smooth workflow.

When doing the sample roasting, extra attentions were paid in order to make sure that the roasting is not getting in the way of cupping. It needs to allow the coffee to speak for itself on the cupping table, so underdeveloped or overdeveloped are both unacceptable when cupping different samples. “It has to hit that middle reference point between the two extremes of roasting.” Can explained. “So far, I am quite satisfied and happy to see that the improvements they are able to make based on our feedback.”

The fact that it will store all the data and roast profiles has proven to be very useful because roasters can easily spot any room for improvements and make adjustments accordingly. This also gives them the freedom to set desired profiles and values, then ask the program to execute accordingly, which has helped the new intern Celeste at Nordic Approach with limited roasting experience to learn and grasp the process with ease and start helping out in the lab as soon as possible.

ROEST so far after two months of intensive use, has proved itself to be up to the task in the non-stop coffee lab.

The Road Ahead

“Our goal from day one was to develop and manufacture a state of the art coffee roaster.” Sverre and Trond both agreed that they have come a long way, only judging by the outlook of different models, you can see the watershed moment in their journey of getting closer to their goal.

What they are really looking forward to in the future is the internet community based on sharing each other’s roasting profile with accurate and standardized data. Potentially, it will also facilitate communication on both ends of the coffee supply chain. Besides this, they are also expecting to see automation playing a bigger role in their software.

As of right now, it still requires certain levels of knowledge of roasting in order to know how to use it, they wish in the future with more data generated every day, their software will be able to suggest roasting profile based on different values like origins, varieties etc., thus substantially reduce the knowledge requirement and also help roasters to optimize their profile more efficiently.

If you are curious what they are up to right now, you can go to their website and feel free to get in touch with them

Menghan, Chau is happy to join Nordic Approach for the next six months as intern, he used to work as Barista in Taipei and Helsinki, originally from Taiwan with a passion for photography and coffee.

0 Comments