Our sourcing strategy

Our sourcing in Rwanda is based on some very solid relationships. We began buying in 2012 and our partners include private producers who own their own washing stations, and one producer with a larger farm (estate), a rare thing in Rwanda. The producers we work with are our portal to the smallholder farmers.

To diversify our offering from Rwanda, and tap the great potential of this origin, we are working on naturals and special preparations, so far with great success. We have such faith in our dedicated partners, we can commit to buying these coffees ahead of the harvest.

The cup profiles

Rwanda is known as the land of a thousand hills, and this is reflected in the coffee. There are as many flavour profiles as there are growing regions.

Our coffees can be divided into 3 main categories:

- Washed from Mahembe with super structured body, a heavy focus on fruit with notes of red berries/black currant.

- Washed from Gitesi with lots of complexity, layers of perfumed florals, transparent and bright.

- Naturals from Gitesi, very sweet and syrupy with ripe red fruit, citrus, florals and great brightness, with a bit of funk to back it all up.

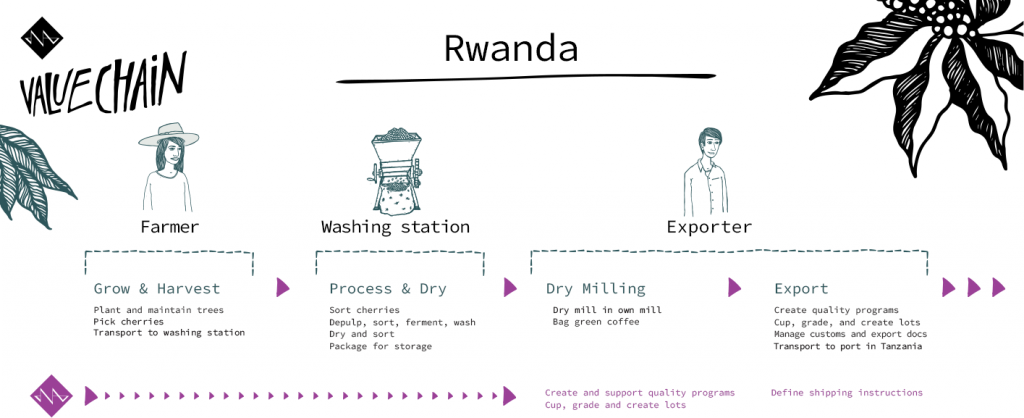

The value chain

When visiting farmers in Rwanda the most common one you’ll meet owns just one hectare of farmland. The farmers deliver cherry to medium-sized washing stations who process and dry the coffee. Washing stations deliver the parchment to exporters who cup and grade the coffee, dry mill and export the finished green coffee.

The relationships

Like all origins, there is a standout year for quality here and there, but in general coffees from Rwanda perform incredibly well every single season.

We have long-standing partnerships with Aime and Alexis from the Gitesi station, and Justin from the Mahembe station. We buy high performing micro-lots from these washing stations, usually 15-50 bags in size.

In 2019 we began experimenting with naturals and special preps with the team at Gitesi. We pre-commit to buying these coffees, regardless of the outcome, so the financial risk is borne by us, not the producers.

Normally the PB beans are sold on the local market for a very low price. We have found these PB lots can really shine with distinct characteristics, so we also buy these at a premium from the same producers.

Over the years of working with these partners we have seen quality improve dramatically, especially in consistency from season to season.

The challenge

Rwanda is still recovering from the political turmoil and tragic violence of past decades, and we see the coffee quality only improving as the country continues its path of recovery.

However while we have no problem finding great quality coffee, there is an oversupply of lower priced Rwandans in the market. We often struggle to sell bigger volumes of higher quality coffees at the premiums we pay. This is something we are working to change by diversifying our inventory with a selection of lower priced PBs (still at higher premiums to the farmer) and natural processed lots.

The “potato’ defect

The Potato Taste Defect (PTD) is a known defect in the coffees from the Great Lakes region. It is caused by a small bug called Antestia that feeds on the cherry and leaves some bacteria, creating a metabolic reaction. Farmers can reduce the risk by using pesticides thoroughly sorting cherries.

There is never a guarantee against any PTD in Rwandan coffees, not even in the best ones, but the coffees are so tasty and such good value for money, it is worth the risk. In collaboration with our producers, using improved picking and intense sorting procedures at every stage of processing, we have managed to reduce the amount of potato in our coffees to a point where it is a minor worry.

Background info

Rwanda is a tiny landlocked country with a very dense population. It’s very poor, but extremely well organised with minimal crime and corruption compared to many other countries in the region. This is of huge benefit for the coffee industry. There are about 500,000 smallholder coffee farmers, and on average they have about 170 coffee trees each. A tiny production!

Farmers usually cultivate other cash crops like corn and bananas. There are about 300 washing stations around the country that generally produce only fully washed coffees. Coffee not processed by a washing station is processed at home and sold as a lower quality coffee on the local market. The altitude ranges from 1200 – 2100 masl. Our producers are working at 1700 masl and up.

Coffee has been a pillar of the Rwandan economy since the 1930s, with the first seeds introduced by Belgian colonialists. However the coffee industry was severely threatened by the global coffee price drop in the 1990s, followed by the Rwandan genocide in 1994 which left the country broken and vital coffee infrastructure destroyed.

Fortunately a lot has changed in the last 15 years. Rwanda has pushed through government reforms that have made it easier to sell coffee. The country has made a remarkable comeback and is now known as a powerhouse of Africa. Projects run by NGOs like Technoserve have had a huge impact on the way producers manage traceability through the supply chain. We believe this is part of the reason why Rwanda so quickly managed to place themselves on the map as a “specialty” coffee origin.

The varieties

Coffees are a mix of cultivars from the Bourbon family, including some developed by the country’s coffee research institute, like BM 139. Other Bourbons include Pop330/21, Mibilizi and Jackson. More seldom is Catuai, Caturra140, and a Typica referred to as Harrare.

Many of the trees are very old, in some cases 50 years or more, but there is also a lot of replanting underway, and new farms starting production. The producers rarely use chemical fertilisers due to their expense. Many farmers create their own organic compost and natural plant treatment products.

Planting and production

The Rwanda season runs from March to August, but we usually make our selections from the May to July pickings. This can always shift a little depending on the region, weather and the altitude of the farm. Farms are generally very small family-owned operations, the family care for the plants and pick the cherries themselves. Usually they will also grow crops for their own consumption, and there are a few farmers with more land.

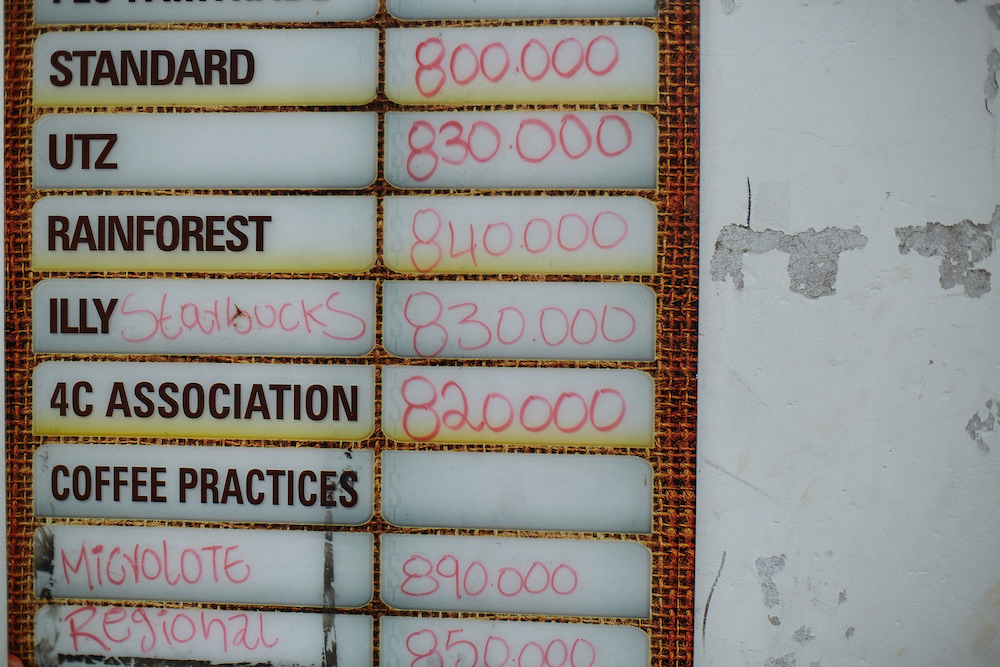

There are normally some hundred smallholder farmers in the local community delivering their cherry to our producers’ washing stations for processing. Our producers are strict on the quality of the cherries delivered by the farmers. If they are not well selected, they must hand sort out the lower quality cherries before the washing station will accept delivery. Competition for cherry can be pretty tough, farmers can deliver to whichever washing station they want, so it’s important that the washing stations maintain good relationships the farmers and offer competitive prices for higher qualities. The producers and their washing station managers often have roots and history with the local community which helps strengthen these relationships.

Processing

Cherry reception

The staff at both Gitesi and Mahembe are very competent, and trained in managing the delivery of cherry from the farmers. They have very strict routines for cherry reception and sorting, cherry delivered by farmers must be sorted by the farmers themselves, if this is not done sufficiently there are staff who will do further sorting. The cherries are placed in a tank prior to pulping where floaters are removed and processed separately as lower grade coffee.

Fermentation, washing and drying

The climate throughout most of the season in Rwanda is relatively cool, which assists in controlling the fermentation process. For the washed processed lots a Penagos 800 Eco Pulper removes the skin, and de-pulps 70% of the mucilage. The coffee is then dry fermented for 10-12 hours. After this the parchment is graded and washed in channels, it is separated into two grades based on density before being soaked under clean water in tanks for 16 hours.

The parchment is initially taken to pre-drying tables, which are under shade, and where, while the parchment is still wet, a lot of hand sorting is done as it is much easier to see defects at this point. The parchment is dried on African drying beds for up to 15 days, during which time the parchment is covered by shade net during the hottest hours of the day, at night, and anytime it rains.

For naturals it is vital to select only the ripe cherries that were picked that same day. For this reason farmers do many passes of their trees, picking only ripe cherries and making small daily deliveries. This is the way to earn the highest prices, rather than doing one pass and having to sell the unripe cherries at a lower price.

Once delivered the cherries are immediately sorted and floated, then laid out on the drying tables in a single layer, with no overlapping cherries, to ensure even air circulation.

During the drying period the team covers the beds with shaded nets when the sunlight is too intense. Plus, while the coffee is on the drying bed, a team hand sort everyday to remove any defective cherries.

At a glance

Harvesting season: March – August

Arrival times: September – November

Quantities: Varies from 15 – 50 bag lots.

Packaging: 60 kg grainpro bags

Price levels: 9,00 – 12,00 USD/kg

Cultivars: Mainly bourbon

Processes: Fully washed and naturals that are dried on African beds either under shade or direct sunlight

Usage: Widely used for filters, as single origin espresso and in espresso blends.

Shelf life: Normally holds up well for a year. We can never guarantee more than 6 months after arrival for any coffees

Rwanda videos

Rwanda blog posts

UGANDA & RWANDA ORIGIN TRIP

UGANDA THE EAST On the 3rd of May, I set out on a 2 week trip to Uganda and Rwanda. After a long night flight, I set my first steps back into the welcoming heat of Uganda’s tropical weather. Quite the contrast with Oslo, where it was still grey and […]

Rwanda 2021 | Looking back

It’s truly a pleasure tasting the finished roasts and thinking back at how they started in the early crop and tasting super fresh. I’m always amazed by what you roasters manage to pull out of it. Jamie Jongkind, Sales EU & Green Buyer January, before the harvest When I first […]

How to plan your buying for Jul – Dec 2021

If you only have 30 seconds, read this: For the second half of the year we will have coffees from Colombia, Brazil, Peru, Uganda, Rwanda, and Indonesia. Samples will start arriving in July/August, and coffees will land from Sept/Oct onwards. Coffees will be slightly more expensive in the coming months, […]