UGANDA

THE EAST

On the 3rd of May, I set out on a 2 week trip to Uganda and Rwanda. After a long night flight, I set my first steps back into the welcoming heat of Uganda’s tropical weather. Quite the contrast with Oslo, where it was still grey and snowy.

Luckily, I didn’t have to face the hoards of taxi drivers asking for attention since I had already arranged one from afar. I could start this new adventure with peace of mind and meet up with the customers joining me at the hotel. After a pretty calm arrival day, we met Christophe, one of our partners in East Uganda overseeing the Bulambuli project, and started our 8 hour drive to Mbale.

On our way to the Bulambuli Washing Station, we passed through Mbale town, driving in the steep, mountainous areas that form Mount Elgon. At 4000 km², it is the largest volcanic base in the world. Its size and beauty are both hard to miss.

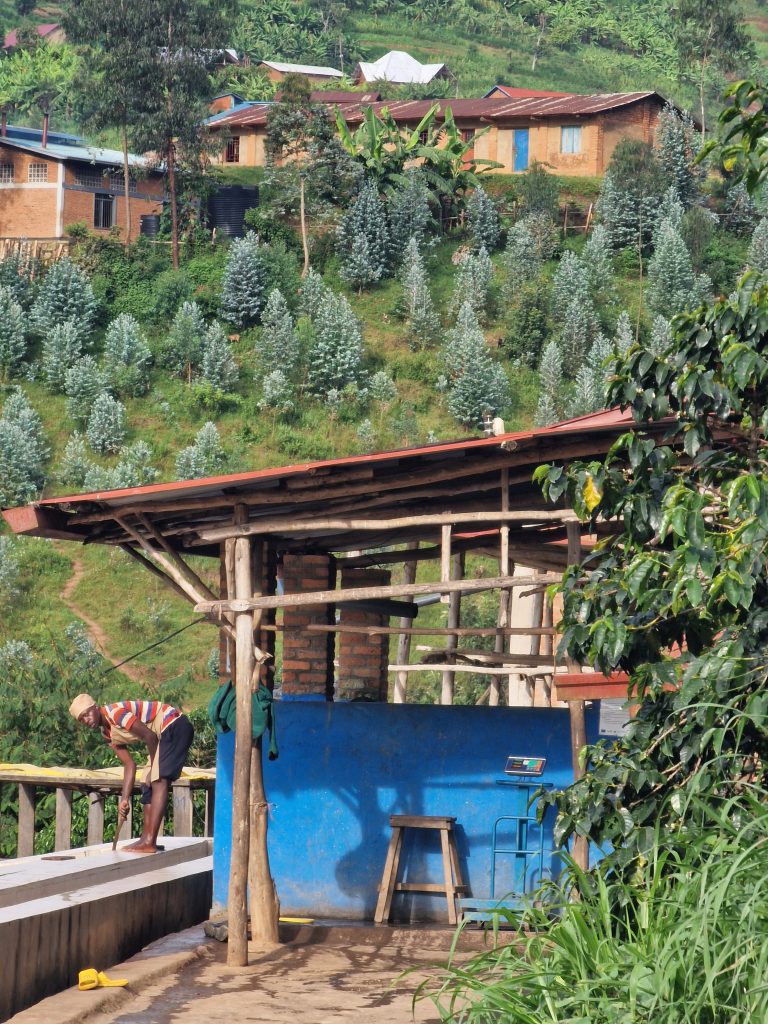

BULAMBULI WASHING STATION

Owned and managed by our partners, Ibero.

You can roughly divide the area surrounding this station into 2 groups: the lower altitudes at 1400-1600 masl harvesting from September to December, and the higher altitudes that go all the way up to 2000 masl. The higher altitude areas get a lot more rain and less sunlight exposure, while harvesting cherry occurs from October to January.

Since the cherries coming in are often from local middlemen, it’s hard to be 100% certain if a lot is coming from a specific altitude group. It’s currently hard to trace a lot back to the hundreds of farmers contributing to the volume collected. Reaching all the coffee growing areas is near impossible, as the terrain is rough to travel in, especially by car. To make up for this and maintain a high level of quality, they do extra sorting of the cherries based on density and size.

The Bulambuli crew also helps distribute fertilisers to the farmers they work with by giving it to them in credit, which they can repay with cherry the following harvest. Incentivising farmers to treat their coffee trees at a high standard while increasing their yield, is a win-win situation for everyone involved. We benefit from this together with farmers and our partners at Ibero, as we get access to better coffee.

If processed correctly, Eastern Uganda is more known for its potential in producing proper, clean washed coffees. Conventionality is not our thing, so we set out to do some really good, clean, or well processed naturals from the East as well.

This is not an easy task for the Bulambuli crew, since it rains all the time. ALL THE TIME.

Something I can attest to from the torrential rain we were greeted with 10 mins after arriving at the station up in the mountains. It made even talking and getting to know each other hard due to the noise. And, as I’m sure you’re aware, “sun-dried” (natural) coffees require…well, sun. And with a lot of rain, there’s not a whole lot of sunshine.

So, they installed a small parabolic dryer to dry the coffees and bring them down in moisture – just enough to safely transport down the mountain to their dry yard in Mbale town.

The term dry yard is primarily used in Uganda. It’s similar to a drying station except that it’s basically just a plot of land with some African drying beds on it, a small storage unit, and a receiving area.

Before heading back down we spent some time getting to know some surrounding farmers and I was happy to see that we did indeed place our trust in the right hands with our partner Ibero. I believe there’s a bright future for both ourselves and the farmers we work with there. For bettering the local farmers’ economies and bringing you the good coffee you’re used to from us.

Honestly, it’s always risky starting a new project and you start anticipating the arrival of the coffee coming in from it and its quality. So far, we’ve been super impressed by the very typical SL profiles and clean processing done by the Bulambuli team.

The eastern part of Uganda has been the region seeing the vast majority of government investment into coffee and you can clearly notice this. Farmers are much more educated, the infrastructure is better organised, and resources are more readily available.

About 40% of arabica in Uganda comes from Mt. Elgon. With no history of robusta, the great soil, the altitude, and the main varieties being SL 14 and 28s, you can begin to understand why most of Uganda’s quality coffee comes from this region.

With that being said, in our humble opinion, the most potential for the future can be found in the West/Nile region. And so we make our way to the next step of our journey, through Uganda’s beauty filled landscapes.

THE WEST

The West is historically known for its home-processed naturals, more so than the East. Generally cheap, and dirty. Of course, this has its use and market. For us, this has not been very convenient since it’s difficult to find producers that are delivering cherry so we can have more control over the quality. However, this is also a challenge that we at Nordic are always looking for, in order to be able to add value to the supply chain and create beautiful coffees for you as the roaster.

Uganda has 10 national parks. One of them, Queen Elizabeth National Park, borders two of the regions we work in. The first region on our trip, where Kihuhire Washing Station is located, is Kasese. To get there, we need to drive back 8 hours on dirt roads to Entebbe Airport and take a tiny 6-seater aeroplane across the planes and jungles of Uganda, towards the West.

Here, we met our new partners in the area, siblings Beth & Jonny, for the first time.

KIHUHIRE WASHING STATION

Owned by Agri Evolve

While taking such an early flight might sound a little tiring, all I could think of is to be back in that small plane with the sun rising over the Ugandan landscape.

After a 2hr flight, we landed at the small Kasese airstrip (a field of grass). You can immediately see the Rwenzori mountains rising in the distance, the place where our coffee in this region is grown. We are greeted and picked up by the kind Beth for the short ride to their family house and new mill facility.

The average farmer here has 1 acre (0.4 hectare) with about 700-800 trees. The farms the Kihuhire station works with are at 1300 – 2000 masl, with the majority sitting at 1500+.

All coffee here is SL 14, 28. There’s no robusta around. For best results, SL 14 is grown at the lower altitudes and SL 28 at the higher ones. This, combined with other general farming practices is also the kind of knowledge Agri Evolve is trying to spread more, to avoid CBD, rust, lower yields, and lower cup quality.

We get the same reports from the people here as in so many other regions: the weather is getting more extreme. They just had 4 months filled with torrential rain, followed by a sudden 3 month drought. From September until December, it has rained every single day.

Agri Evolve is supporting surrounding farmers in this area with technical knowledge, finances and has a seedling nursery program, buying seedlings to distribute to farmers. This is essential as the UCDA* spread a lot of seedlings (millions) in Kasese in the past, but of very poor quality. Combined with poor knowledge of coffee farming practices, most died.

*The Uganda Coffee Development Authority, a government agency established to increase quality coffee production, productivity and marketing.

Most of the coffee here is drugar: a local home-processing method used for generations, resulting in a dried, cheap, and low quality coffee but slightly fruity. Jonny & Beth are trying to change this by getting farmers to deliver them cherry instead.

They’re slowly, but surely, making an impact. 8 years ago, 99% of coffee in this area was drugar, whereas today it has fallen to 90%. Not only does this improve cup quality, but it also has more potential economically. Either way, they buy all the quality the farmers deliver.

At the house, we met the rest of the family trio that’s behind this business; Jonny and their father Martin. This is our first time ever meeting anyone from this project, so I was very excited to get to know them all.

The house has been temporarily changed into an office space while they’re constructing a new one next to their mill. So the cupping room we’re later using to evaluate some of the coffees is Martin’s old bedroom – but even though it’s all temporary I really liked the functional set up and was happy to be able to cup through a range of their coffees there to get a better idea of their work. A range from low to high altitude and different sorting and processing.

Jonny brought us to his area of expertise, the relatively small but very new and state-of-the-art mill just across the dirt road – a 1-minute walk from their home. On the way there we met Charles, a man with a giant smile. Charles, the factory manager, knows Jonny from back when he was born, as his father has been in this area for a long time.

The entire plot is big, 20 acres. Entering the gate, the drying yard and office that’s under construction are directly on your right.

The mill and washing station are under the same roof and were built only 1.5 years ago. The site starts at 1500 masl and goes all the way down to 1100 masl. The coffee is delivered and sorted into coloured crates, differentiating between ripe cherries and underripes.

With gravity, the cherries go from the cherry hopper and de-pulper up through the grading channels and into the fermentation tanks. In between, the cherries are removed and taken to the drying yard next door until the moisture and water activity has dropped enough. The coffee is then ready to continue downstream to the mill where it is dried further in mechanical driers and sorted for density and imperfections until it’s processed to the proper quality grades and stored in GrainPro bags.

I was very impressed by the thought and planning that went into the mill, well streamlined and minding the details from start to end where the milled coffee leaves the facility for its journey to Kampala and on to Mombasa, Kenya where it’ll continue on a boat to our warehouse in Belgium.

Next, Beth brought us to her expertise, the field. And it shows, this is where she shines and lights up. It’s a blast driving through the towns and dirt roads surrounding their mill as everyone in town seems to know her and they frequently hitch a ride to/from work as Agri Evolve employs a lot of people in the area.

They employ about 100 people seasonally and 85 permanent staff members with 30 full time positions in the field. They work with thousands of farmers they buy coffee from. Most of the farmers in the higher altitudes grow organically, by default, and around a 1000 are certified. Certification is not necessary per se, but it gives some additional options for the future of this project. For us, the pillars of Nordic’s vision are there already; human wellbeing, farm practices, and (potential) cup quality.

Transporting coffee from the farmers in the mountains is very problematic. Cherry gets stuck in the fields due to rain, regular floods and bad roads. Most transport is during the night, giving extra difficulty as most farmers pick in the morning and afternoon and sell their cherry in the evening.

They found an innovative way to create local “collection points”, functioning and looking more like a small community store. Farmers can exchange their coffee for cash or, if they choose, directly into products like soap or other vital household goods. These stores were one of the highlights for me in the end, they turned out to be these cultural gathering points with a bunch of people meeting and sitting around chatting.

After this pleasant, first-time visit, we continued our journey to the south part of Uganda where we met the crew from Kingha, a partner we have happily worked with for 3 years now.

Overview of the seasons here:

Flowering January and harvesting Feb – May

Flowering August and harvesting Sep – Dec.

KINGHA ESTATE

The road from the Kasese area to the Kingha Estate makes you drive right through the Queen Elizabeth National Park with some quite unique experiences (like an elephant rushing your car to mark its territory, you know, the normal day to day things).

Besides that, the Kingha Estate also borders the Bwindi Impenetrable Forest which treated us to a silverback gorilla just casually walking around, munching on some leaves when we visited the border of the park later that evening.

It was wonderful being back in the Kihihi area and the Kingha Estate. I wrote about my wonderful experience there in full length in the past.

Something that still sticks out to me is how difficult it is to get cherry from the rough mountainous areas where the farmers are located. The trips are done with boda bodas, the name for the local motorcycles and their drivers. In the end, it’s all worth it considering the quality coffee we’ve been getting from the Kingha Estate. They still provide us with some incredibly good washed, natural, and anaerobic processed coffees.

It was good meeting the new manager of the station and seeing that it is in very capable hands for the next seasons to come.

After 2 nights in the jungle-like area, a day of visiting the station and fields, and a very welcome “late” morning wake up (7am), we continued our path to the Rwanda leg of the journey.

RWANDA

THE WEST

What can I say? GOOD TO BE BACK IN RWANDA!

Just having been in Uganda for a week, you enter a completely different country and vibe yet both so very African and similar in other ways. It’s been four years since I was last in Rwanda, with Covid postponing my previous plans to visit. I was anxious to meet up with my friends and partners at the stations.

Sadly, it wasn’t all fun as a few days before my visit, the area witnessed destructive floods and landslides that resulted in people dying and losing their homes. We’re thinking of ways we could contribute and help them out and hope to tell you more on that in the near future.

MAHEMBE WASHING STATION

As we were making our way up the mountains, we had to stop at some point because the recent flooding had destroyed a road going into the area and we continued on foot. Luckily, it wasn’t that far and we reached Mahembe around 11am.

Last time I was here I met the station’s owner, Justin. This time, we were greeted by his son, Willie, who is now fully managing the Mahembe station.

At only 23 years old, an age at which most of my western friends couldn’t even clean up their own room, I was incredibly impressed by his calmly formulated expertise and oversight of the station. He was 100% in control and it was a delight talking to him as I could flood him with my curiosity and all of my questions.

He showed us around all the new improvements. It was truly fantastic to see they had invested so much in the facility. Everything looked fresh and new.

There is a roof over the entire area from where they are receiving and registering the cherry coming into the de-pulping, sorting, grading and fermentation tank area.

On the top of the hill, in the back of the drying area, they have created a big multi-story and completely shaded drying facility and I can’t wait to taste more coffees coming out of it.

It makes it a lot easier for the Mahembe staff to dry coffee, since it has multiple stories and it can open or close the walls on every side depending on the rain for more airflow; it is therefore also capable of more homogeneously dried coffee. It brings more control over drying and therefore increases quality.

Justin has also bought up more land in recent years and is already growing coffee on most of it, some areas even having their first crops. They’ve definitely been busy!

One piece of his land, “Gituntu”, is located at 1900 masl and planted with 53.000 trees, now 4 years old producing over 17 tons of cherry.

The new land, named “Murundo”, is located at 2200 masl! This new area has 68.000 trees on it, now just 2.5 years old but already producing 6 tons of cherry. The cherry here has a bit less sun and thus takes a bit longer to develop and ripen on the trees.

Definitely looking forward to tasting more of that in the future, especially taking into account how awesome the Mahembe quality has already been the last 10 years and how crazy good the cup profiles are from the soil in this area.

In total, Mahembe gets about 10% of cherry from their own land and 90% from the surrounding smallholder farmers. Increasing that percentage of their own land can be great. It probably sounds less “romantic” than working with more smallholders, but having at least a good percentage in your own control is extremely beneficial – to stabilise the amount of yield and increase quality every year. Since you have much more direct control of farm practices.

Currently, they have a hand-made pulper but have already installed a new Penagos after being hit by lightning a while ago that completely destroyed the old de-pulper and part of the facility. This new one will be up and running for the next harvest.

They actually do have 2 crops here, but the fly crop results in only 15% of total production and has too much sun and drought.

Something interesting to note about the volatility in the cherry pricing in the world. As an outsider, especially from the west, you’d think that higher prices only result in benefits. This is definitely the case, but perhaps not as much and not as long-term as you’d think.

The cherry prices paid to farmers went from 600 RWF/kg of cherry in 2021 to suddenly 900 RWF/kg in 2022 (an increase of 50%.). This sounds incredible for the farmers, which it was that year.

However, lots of stations went bankrupt and were bought by the big players. This isn’t necessarily beneficial long-term since the farmers will have less choice where to bring their cherry to.

Sadly, we were on a pretty tight schedule and had to continue to the west to make it to Gitesi on time.

GITESI WASHING STATION

We arrived late in the afternoon and I can’t say how good it was to be back at Gitesi and seeing Aime, the owner, after such a long time away. I honestly can’t really describe Aime’s personality well enough. He is such a kind and warm hearted person to see and work with. He seems to radiate calmness and joy for life. His love for coffee, people, and nature is wonderful and contagious like the big permanent smile on his face.

What was equally beautiful to see is all the improvements made to the station and area. Wow!

It honestly warmed my heart to see the evolution and how a long-term partnership can embody itself in physical improvements that make everyone’s lives working there a lot better.

They now have a small building with a hall to properly store parchment in and a tiny office where he proudly displayed some of the bags from roasters working with his coffee.

Walking in the area surrounding the drying tables felt like nature had returned there. There were loads of birds singing and his tiny “vegetable-pilot” project of a few m2 turned into a big botanical gardens-like area growing an incredible diversity of (non-coffee) sustenance plants and yearly crop rotation to enrich the soil.

He has big plans of making a small house for visitors to be able to stay there and cook with him and learn about coffee, something we proudly look forward to participating in.

Later that day, we sat down to brew some of his own coffees to serve to him and he offered some incredibly tasting honey from the bees he keeps at the station. I let him talk while I just ate spoons full of this delicious tropical-tasting liquid gold.

Honestly, there’s not a whole lot to say about the quality of Gitesi since it has steadily been improving over the years and we have not had one bad year in the last 10 years we’ve been working with them. It’s one of those stations we can 100% rely on to perform and deliver high-scoring complex and characteristic coffees.

He continues to improve by slowly replacing all the old beds with new double-floor beds, shaded below, normal above. They have the possibility to swap depending on the weather and how fast or slow you want a coffee to dry.

For your understanding, an old bed costs around 300.000 RWF (about 265,- USD as of June 13th ‘23) and the new one costs double that at 600.000 RWF. It’s really expensive but also a really good investment long term as quality, volume, ease of handling and longevity goes up.

As long as you keep buying their coffees, they will keep investing and improving! We’re looking forward to another 10 years with Gitesi & Mahembe and to creating better relationships between you, the roasters, and them, the producers. Opening the circle of coffee production for cross contamination of all inspiring minds to contribute and participate.

I look forward to my next trip to our producers and friends, I hope you do too.

Have a beautiful week and hope to see you in Athens, Greece for this year’s World of Coffee.

0 Comments